LO 5-3820-239-12

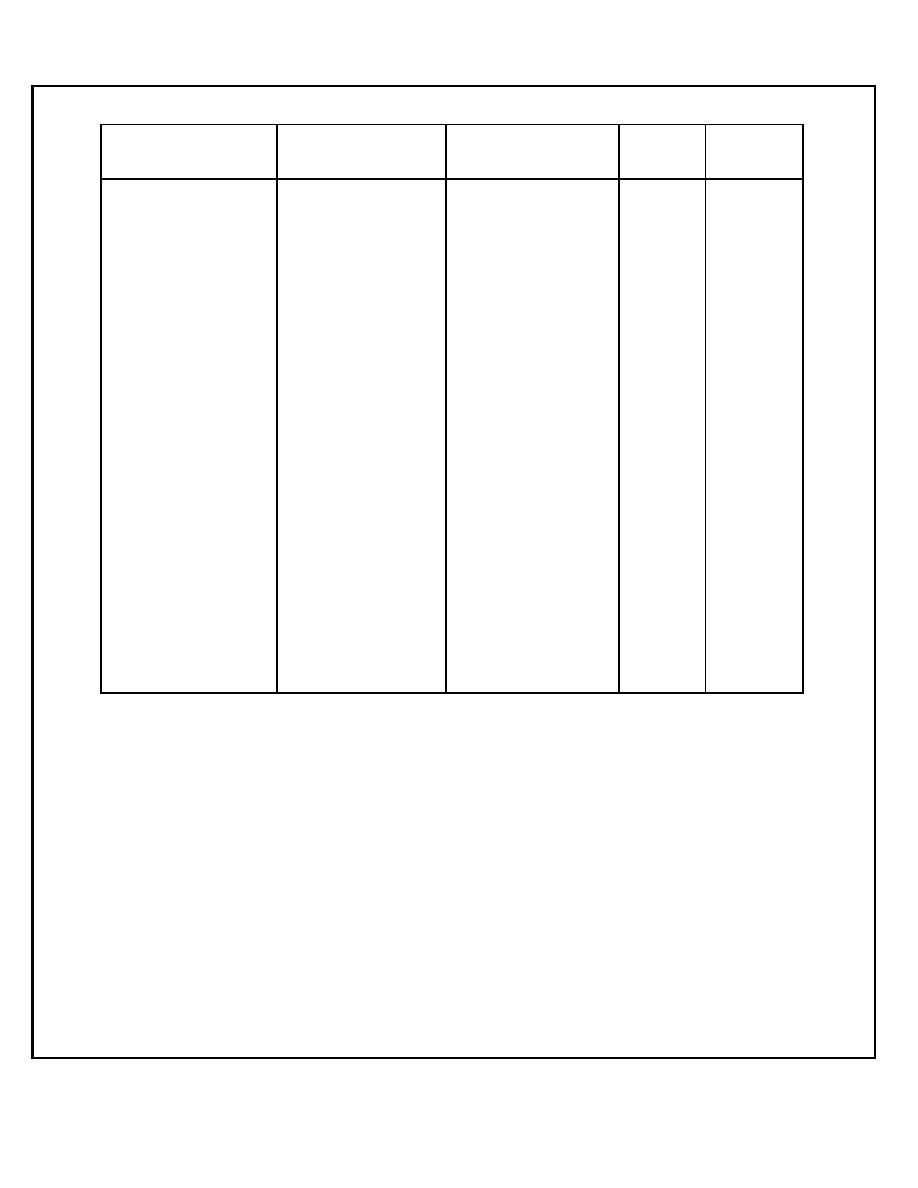

Table 1. Lubricant Table For Pneumatic Drill

Temperature

Lubricant

Range

Mil. Symbol

Capacity

Interval

Man-hour

Specification

Above + 15F

OE/HDO 30

2 qt (1.89 I)

10 H

(-9C)

MIL-L-2104

(propelling air motors)

40 qt (37.84 I)

(hydraulic reservoir)

50 H

GO 80W/90

1 1/2 qt (1.42 I)

50 H

MIL-L-2105

(air feed motor)

+40 to -15F

OEIHDO 10

2 qt (1.89 l)

10 H

(-4 to -260C)

MIL-L-2104

(propelling air motors)

40 qt (37.84 I)

(hydraulic reservoir)

50 H

GO 80W/90

1 1/2 qt (1.42 I)

50 H

MIL-L-2105

(air feed motor)

+ 40 to -65F

OEA

2 qt (1.89 I)

10 H

(+ 4 to -540C)

MIL-L-46167

(propelling air motors)

40 qt (37.94 I)

(hydraulic reservoir)

50 H

GO 75W

1 1/2 qt (1.89 I)

50 H

MIL-L-2105

(air feed motor)

All

GAA

MIL-G-10924

All

GMD

NOTES:

1. FOR OPERATION OF EQUIPMENT IN PROTRACTED COLD TEMPERATURES BELOW -15F (-260C). Remove

lubricants prescribed in Table 1 for temperatures above -15F (-26C). Relubricate with lubricants specified in Table 1 for

temperatures below -15 F (-26 C). If OEA lubricant is required to meet the temperature ranges prescribed in Table 1, OEA

lubricant is to be used in place of OE/HDO-10 lubricant for all temperature ranges where OE/HDO-10 is specified. For

arctic operation, see FM 9-207.

2. OIL CAN POINTS. Each 50 hours lubricate control linkage, clevises, control shaft slip joints, and all exposed adjusting

threads with OE/HDO.

3. HYDRAULIC TANK. Each 50 hours check level. Correct level is 5 inches below top of tank. Fill to level with OE/HDO.

4. HYDRAULIC SYSTEM OIL STRAINER. Each 1000 hours remove strainer, clean with dry cleaning solvent, dry, and

reinstall.

5. HYDRAULIC SYSTEM FILTER. Each 1000 hours remove element, clean filter shell, and install new element. After

replacement, operate hydraulic system for 5 minutes, check for leaks, check level, and bring to full mark.

Card 10 of 12