b.

Store the pneumatic rock drill in the

maximum stability position as shown in figure 24, when

not in operation.

Figure 2-4. Maximum stability position for rock drill

tramming and storage.

2-5.

Operation of Equipment

a.

Tramming the Rock Drill.

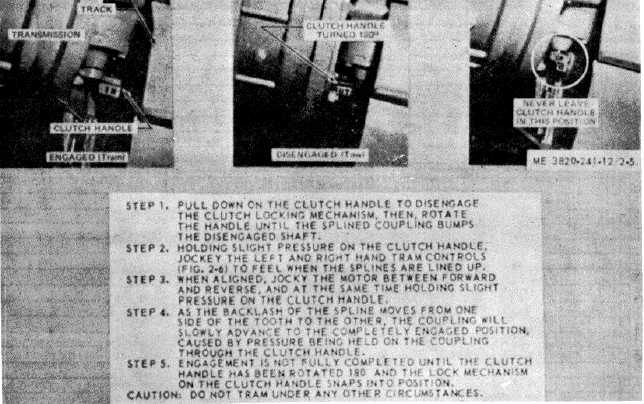

(1) Operation of Tram Clutch. The internal

clutch mechanism for each tram motor operates by a

sliding, splined coupling that couples two splined shafts.

When the coupling is all on one shaft, the tram motor is

disengaged from the drive sprocket (towing position).

When the coupling is half over each of the male splines,

the gear train is in tramming position. There are no

intermediate positions that are satisfactory. Figure 2-5

shows the proper engaged position, disengaged position,

and the wrong position of the clutch handles.

Figure 2-5. Engaging the rock drill for tramming.

(2) Connecting Air Supply. Secure the air

compressor to the rock drill and connect the main air

supply hose as illustrated in figure 2-2.

(3) Engaging for Tramming.

(a) Start the air compressor (para 2-3) and

operate the tram motors to make sure they rotate freely.

(b) Engage the rock drill for tramming as

illustrated in figure 2-5.

(4) Disengaging for Towing.

CAUTION

Disengage the clutch only when rock drill

is parked on terrain that will not allow the

rock drill to run free. When disengaging,

it may be necessary to jog the tram

motor back and forth so the backlash

will relieve any external pressure that

may be opposing engagement.

WARNING

It is possible to tram the rock drill with

the clutch partially disengaged as shown

in circled view of figure 2-5. In this

position, it is also possible for the clutch

mechanism to slip out of engagement,

allowing the drill to run away.

2-7