(8) Carefully check air tube (6) for splits, cracks,

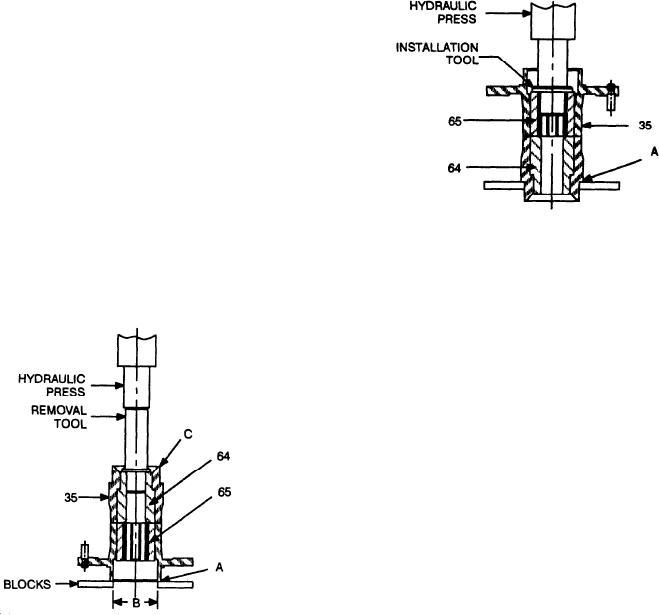

(17) To install chuck bushing (64) and driver (65):

scoring, or excessive wear, particularly in the first 4 in.

(a) Set carrier (35) in hydraulic press as shown.

where the air tube contacts striker bar. Replace cracked,

Rest face A on blocks.

split, scored, or worn air tube.

(b) Using fabricated installation tool (see Ap-

(9) Inspect plates (39 and 44) for sharp edges and

pendix B), press chuck bushing (64), beveled face up, into

wear. Remove all sharp edges and hone to clean.

carrier (35) until seated.

(10) Check inside diameter of front bushing (2). If

(c) Using fabricated installation tool, press

inside diameter is greater than 1.285 in., replace front

chuck driver (65) into carrier (35), using the minor diame-

bushing. If front bushing can no longer be kept tight be-

ter of the spline marks as a guide.

cause of excessive wear on inside face of front cap (1), re-

place cap.

(11) Check for wear on retainer (26) and both sides

of spring washer (27). Replace if worn.

(12) Inspect gland plug (4) for damage and wear.

Replace if damaged or worn.

(13) Inspect chuck bushing (64) inside carrier (35).

If striking bar imprint is 0.050 in. or greater, replace chuck

bushing (see step (16) below).

(14) Check inside diameter of chuck bushing (64). If

inside diameter is greater than 1.405 in., replace chuck

bushing (see step (16) below).

c. Assembly.

(15) Check splines on chuck driver (65). If splines

(1)

Tap bearing cup (50) into main housing (51).

are worn half through, replace chuck driver (see step (16)

(2) Install new gasket (59) and cover (58) on main

below).

housing (51) using four screws (56) and new lockwashers

(16) To remove chuck bushing (64) or chuck driver

(57).

(65):

(3) Install new gasket (55) and manifold (54) on

main housing (51) using four screws (52) and new lock-

washers (53).

(4)

Install grease fitting (60) in main housing (51).

(5) Press two shafts (37) into flange (38). Carefully

orient ends of shafts so that they will properly key into

slots in plate (39) when installed.

(6)

Install gear (45) on each shaft (37).

(7) Place two bearings (41) and spacer (42) in be-

lower than surface of gears.

(8) Seat motor housing (40) on flange (38). Aline

two dowel pin holes and tap in two dowel pins (36).

A

(9)

Install air motor gear (43) on flange (38).

BLO

l+H

(10) Install front plate (44) on dowel pins (36) and

(a) Set carrier (35) in hydraulic press as shown.

shafts (37) and gently tap in place.

End A should rest on blocks set far enough apart and deep

(11) Press three shafts (48) into carrier (35). Install

enough to allow clearance for the chuck bushing (64) and

three nuts (49) and secure with thread-locking compound.

driver (65) to be pressed through B. Do not attempt to

(12) Press bearing cone (46) onto carrier (35).

press out parts with carrier resting on face C.

(13) Slide gear (47) onto each shaft (48).

(b) Insert fabricated removal tool (see Appen-

dix B) between press and chuck bushing (64) as shown.

(14) Set carrier (35) face down and slide air motor

assembly (31) onto carrier. Ensure gears mesh properly.

(c) Press chuck driver (65) and bushing (64) out

(15) Press bearing cone (34) onto carrier (35).

of carrier (35).

9