TM 5-3820-241-34

Section III. DRIFTER DRILL

5-9. General

a. Description. The pneumatic drill engine is a

heavy duty percussion machine designed for deep

hole drilling in hard rock. The drill incorporates a

dual rotation assist unit integral with the drill to

provide a fast method for coupling and un-

coupling the drill steels, and to furnish a power

assist to normal rifle bar rotation. The dual

rotation unit consists of an independent vane type

air motor geared to rotate the chuck in either

direction. Operating controls for the drill and

allied functions are mounted on the feed.

b. Theory of Operation. There are two basic

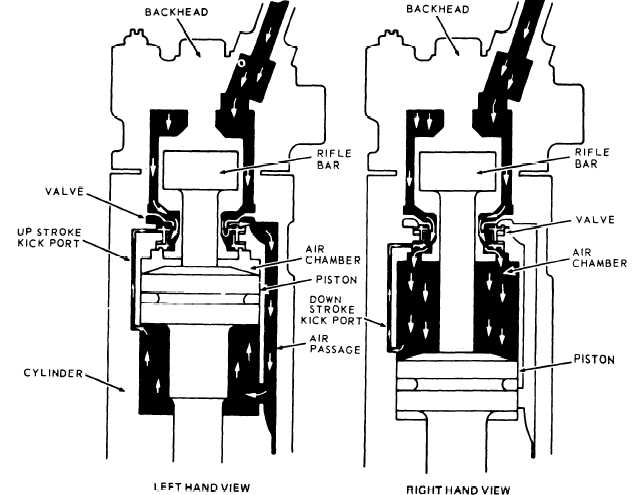

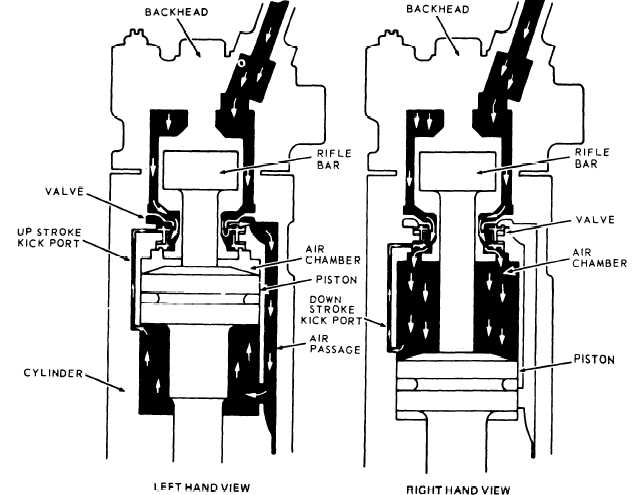

Figure 5-5. Drifter drill valve operation.

operating principles involved in the action of the

drill engine. First, the principle that makes the

piston reciprocate in the cylinder, and second, the

principle that causes the drill steel to rotate.

(1) Piston Reciprocation. Back and forth

movement of the piston is affected by a self-

acting or automatic valve that admits air at the

proper instant, first to one end of the cylinder

then to the other end. Figure 5-5 illustrates the

involved portion of the drill engine in cross

section. The left hand view shows the piston at

the top part of the cycle, and in the right hand

view, the piston is in the bottom part of the cycle.

ME 3820-241-34/5-5

(2) Value Operation.

In figure 5-5 (left hand

view) the piston is shown moving to the up-

permost part of the cycle. Just before it reaches

the top of the chamber it uncovers the air kick

port that allows air to flow through the kick port

to the backside of the valve. This pressure causes

the valve to close the air supply to the back end of

the cylinder and to admit air to the front end

5-7