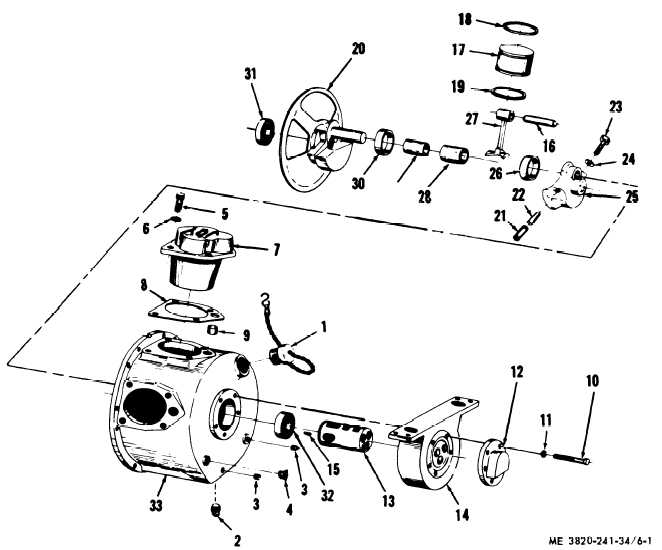

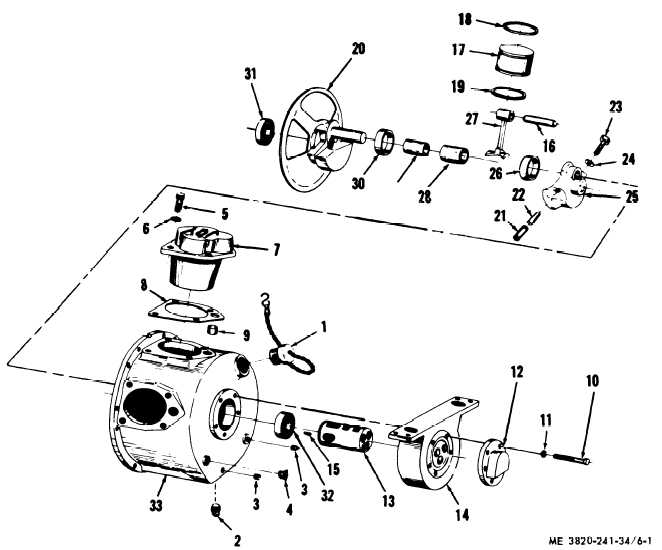

TM 5-3820-241-34

1 Oil filler cap assembly

12 Exhaust cap deflector

23 Hex head capscrew

2 Oil drain pipe plug

13 Valve assembly

24 Washer

3 Oil level pipe plug

14 Rotary valve housing

25 Counterbalance

4 Oil level cock

15 Straight pin

26 Retaining ring

5 Hex head capscrew

16 Piston pin

27 Connecting rod

6 Lockwasher

17 Piston

28 Bushing

7 Cylinder assembly

18 Compression ring

29 Sleeve

8 Cylinder gasket

19 Oil ring

30 Retaining ring

9 Air orifice

20 Crankshaft assembly

31 Ball bearing

10 Hex head capscrew

21 Headless setscrew

32 Ball bearing

11 Lockwasher

22 Taper pin

33 Motor housing

Figure 6-1.

Tramming motor, disassembly and reassembly.

(2) Wedge two screw drivers between the

valve housing (14) and motor housing (33) to pry

the valve housing loose.

(3) If cylinder (7) is tight in the housing, use

a rubber or plastic mallet to free them.

(4) Rotate the crankshaft (20) to bring each

piston pin (16) above the motor housing (33), then

push out the pin and remove the piston (17).

(5) Pull the crankshaft (20) with attached

6-2

connecting rods (27) out of the motor housing (33)

by shifting the connecting rods to clear the

cylinder holes.

6-3. Tramming Motor, Cleaning, Inspection and

Repair

a. Cleaning. Clean all parts except the

bearings and gasket in cleaning solvent (FED

SPEC PD 680) and dry thoroughly.