TM 5-2590-512-13&P

SECTION V. UNIT MAINTENANCE PROCEDURE

4-29. Shaft Bearing and Seal Service.

This task covers:

a. Service

Initial Setup

Tools:

Equipment Conditions:

General Mechanic's Tool Kit

Output shaft removed (see para. 4-26)

5180-00-177-7033

Materials and Parts:

GAA Grease, P-D-680 Dry Cleaning Solvent. Rags.

a. Service.

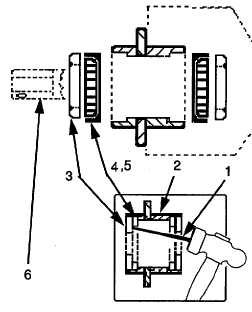

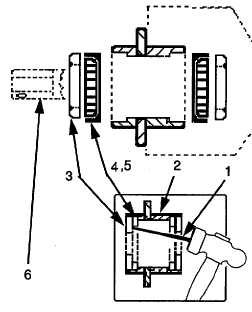

1.

Insert drift (1) into hub (2) thru top hub opening and gently tap

out (on metal exposed part) lower seal (3). Remove lower

bearing cup (4) with lower bearing cone (5).

NOTE

Leave upper bearing cone and cup and seal in place.

2.

Carefully inspect the drive shaft (6) and the inside of the hub

(2) for any cracks, breaks, bends, visible wear, or general

defects. Rotate bearings to check for rough spots or

symptoms that bearings need replacement. Replace any

defective parts.

WARNING

Dry cleaning solvent P-D-680 is toxic and flammable.

Wear protective goggles, face mask, and gloves and

use only in a well ventilated area. Avoid contact with

skin, eyes, and clothes, and don't breathe vapor. Do

not use near open flame or excessive heat. The

flashpoint for Type I dry cleaning solvent is 1000F

(380C) and for Type II is 1400F. (600C). If you become

dizzy while using cleaning solvent, get fresh air

immediately and get medical aid. If contact with eyes

is made, flush eyes with water and get medical aid

immediately.

3.

Wipe excess grease from inside hub (2) with clean rags.

Clean bearings one at a time with solvent and immediately

apply grease. Rotate bearing as you work grease into cone

and cup surfaces.

4.

Install lower bearing cup (4) and lower bearing cone (5) in hub

(2).

5.

Use cylinder shape tool on lower seal (3) surface to apply

uniform force and tap seal in place in hub (2).

FOLLOW ON TASKS

Install Output Shaft (para 4-26).

END OF TASK

4-30