f: Other Table Entries. Be sure to observe all special

use the equipment. DURING procedures must be done

during the time you are operating or using the equipment

information and notes that appear in you table.

for its intended mission. AFTER procedures must be

3-7.

Leakage Definitions.

done immediately after you have operated or used the

equipment. WEEKLY procedures must be done once

The following are definitions of the types/classes of

each week. QUARTERLY procedures must be done every

leakage you need to know to be able to determine the sta-

three months or after 250 hours of operation, whichever

tus of your equipment.

comes first.

CLASSIFICATION DEFINITION

c. Location, Item to Check/Service Column. This col-

Seepage of fluid (as indicated by

Class I

umn provides the location and the item to be checked or

wetness or discoloration) not

serviced. The item location is underlined.

great enough to form drops.

d. Procedure Column. This column gives the proce-

Leakage of fluid great enough to

Class II

dures you must do to check or service the item listed in the

form drops but not enough to

Check/Service column to know if the equipment is ready

cause drops to drip from the item

or available for its intended mission or for operation. You

being inspected.

must do the procedure at the time stated in the interval

column.

Leakage of fluid great enough to

Class III

e. Not Fully Mission Capable If: Column. Information

cause drops to drip from the item

in this column tells you what faults will keep your equip-

being inspected.

ment from being able to perform its primary mission. If

Note: Fluid levels of items with Class I and Class II leaks must be

you make check and service procedures that show faults

checked often so proper levels can be kept.

listed in this column, do not operate the equipment. Fol-

low standard operating procedures for maintaining the

Class III leaks must be reported to supervisors or to Organizational Level

equipment or reporting equipment failure.

Maintenance for corrective action.

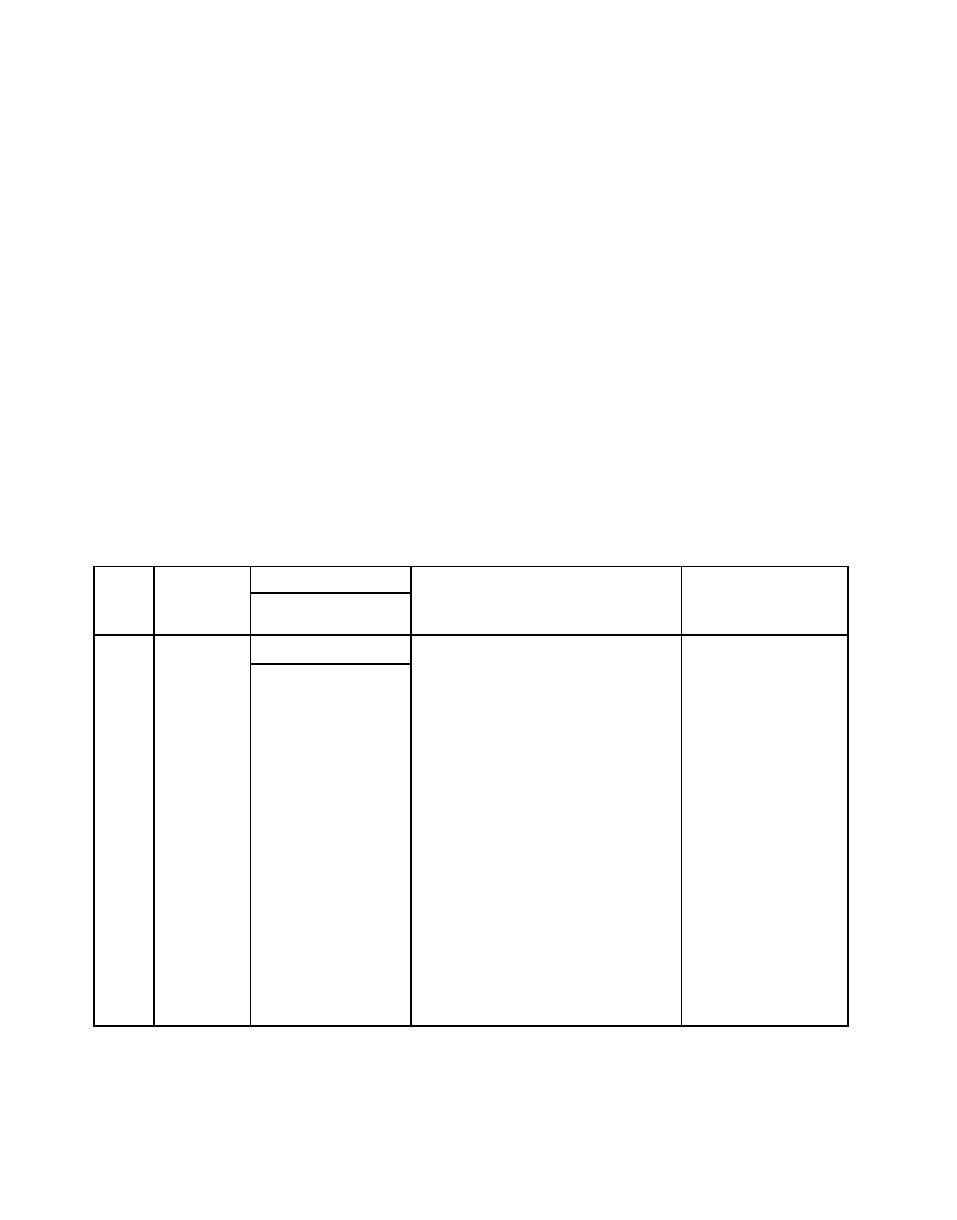

Table 3-1. Operator Preventive Maintenance Checks and Services for Crawler-mounted Rock Drill

Location

Not Fully Mission

Item

Procedure

Interval

Item to

Capable if:

No.

Check/Service

Crawler

Check hoses and fittings for good Signs of Class III leak-

Hydraulic Hoses and

1

Before

condition. Ensure that fittings are tight. age.

Fittings

Look for signs of leakage around hydrau-

lic hoses.

Check oil level. Notify organizational

Lubricating Oil

2

Before

maintenance if level is low.

Reservoir

Check oil level. Notify organizational

Traction Drive Planet

Before

3

maintenance if level is low.

Gear Housing

Check oil level. Notify organizational

Propelling Air Motors

4

Before

maintenance if level is low.

Check hydraulic control valves for leaks.

Class III leaks are

Hydraulic Control

During

5

found.

Valves

Adjust flow to drill (see paragraph 3-10).

Lubricator Metering

During

6

Valve

Check oil level. Oil level should be 5 in,

Hydraulic Reservoir

Weekly

7

below top of reservoir. Notify organiza-

tional maintenance if level is low.

4