Table 3-2. Organizational Preventive Maintenance Checks and Services for Crawler-mounted Rock Drill

NOT FULLY

ITEM TO BE

ITEM

MISSION

PROCEDURE

INTERVAL

CHECKED OR

NO.

CAPABLE IF:

SERVICED

Note: Checks 1 through 4 are for units

equipped with retrofit kit.

Any bolts loose or

Check all bolts and nuts on feedshell for

Feedshell

Weekly

1

missing.

tightness. Pay particular attention to

drifter drill mounting bolts and feed-

shell slide mounting bolts.

Chain cannot be ad-

Check chain deflection weekly. Ensure

Feed Chain

2

Weekly

justed.

that chain is not so tight that no deflec-

tion occurs not so loose that is sags. Ad-

just if necessary (see paragraph 3-25 or

7-13).

Air Hose Connections Check all air hose connections and

Weekly

3

tighten if necessary.

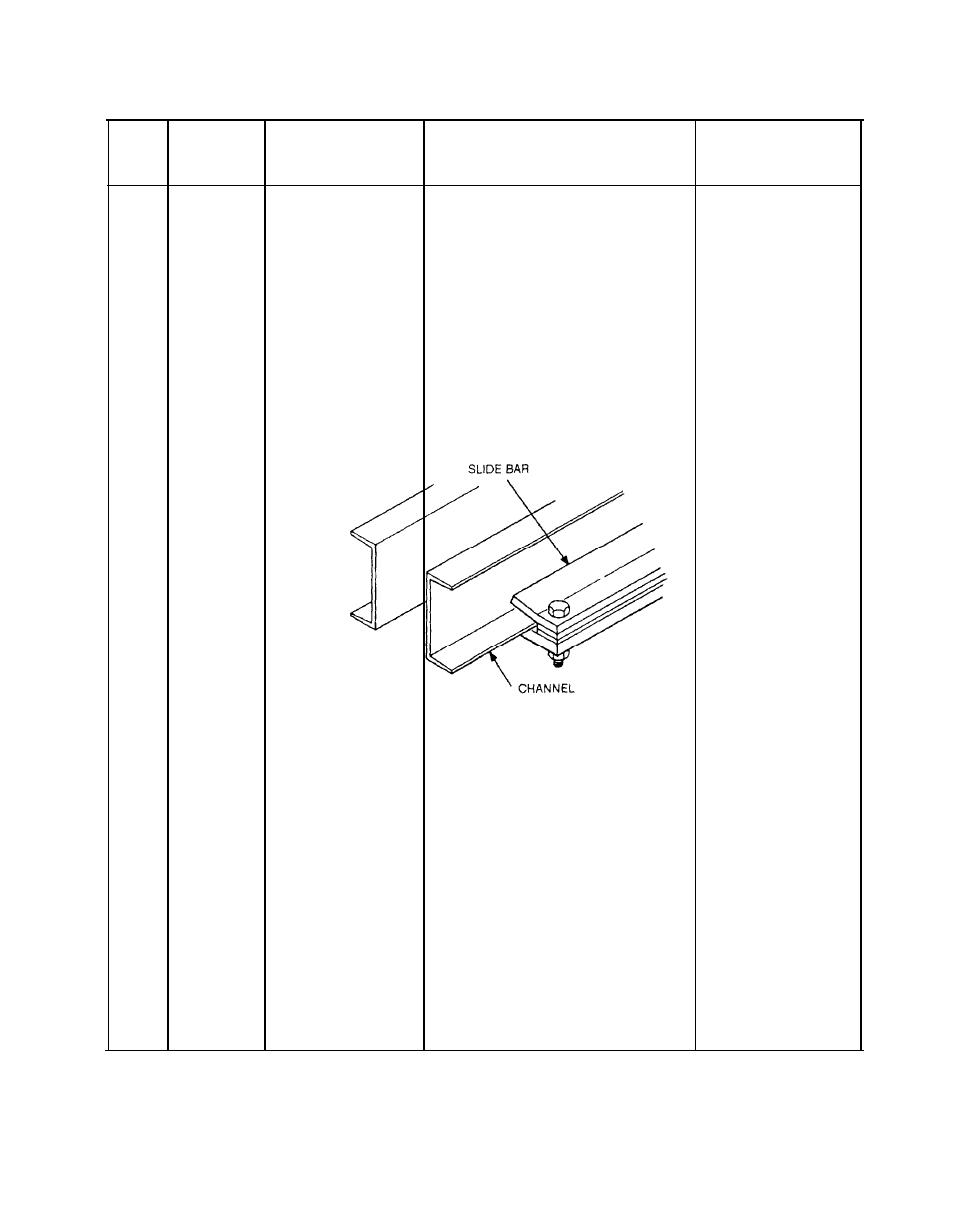

Measure clearance between slide bar

Slide Bar Shims

4

Monthly

and feedshell channel. If clearance is

greater tha: 1/8 in., remove slide bar and

adjust shims until clearance is less than

1/8 in. (see paragraph 7-12). Repeat for

all four slide bars.

Centralizer

Close centralizer and measure inside di-

Monthly

5

ameter of bore. Replace centralizer

blocks when inside diameter is greater

than 2 in. (see paragraph 7-9).

Check torque on side rod mounting

Drifter Drill

6

Monthly

nuts. Gradually tighten to 150 lb-ft.

Adjust brakes (see paragraph 3-38).

7

Brakes

Quarterly

Check and tighten sprocket stud nuts if

Final Drive Sprockets

Quarterly

8

required (see paragraph 3-36b).

(Check and adjust tracks if requircd (see

Tracks

9

Quarterly

paragraph 3-36b).

6