TM 5-3820-241-34

ME 3820-241-34/5-4

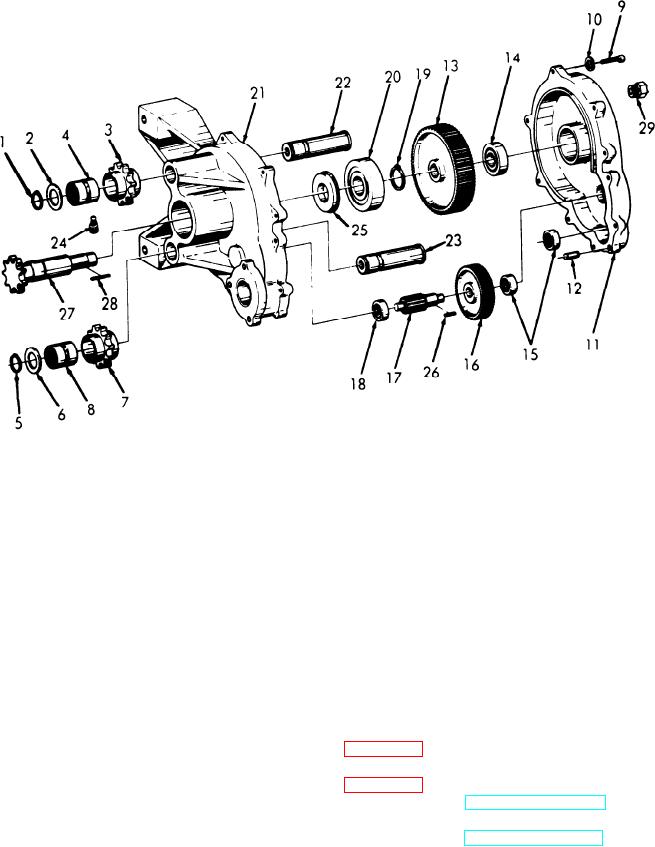

22

Idler gear shaft

15 Ball bearing

8 Roller bearing

1

Snap ring

23

Idler gear shaft

16 Spur gear

9 Hex head capscrew

2

Sprocket washer

24

Lubrication'fitting

17 Spur gear

10 Lockwasher

3

Sprocket idler

25

Shield

16 Ball bearing

11 Transmission cover

4

Roller bearing

26

Gear to shaft key

19 Snap ring

12 Dowel pin

5

Snap ring

27

Drive sprocket

20 Ball bearing

13 Main drive gear

6

Sprocket washer

28

Drive sprocket key

21 Transmission housing

14 Ball bearing

7

Sprocket idler

29 Vented plug

Figure 5-4. Feed transmission, disassembly and reassembly.

5-8. Feed Transmission, Reassembly and In-

5-7. Feed Transmission, Cleaning, Inspection and

stallation

Repair

a. Reassembly.

a . Cleaning. Clean all parts with cleaning

(1) Lubricate all components with a light

solvent (Fed Spec PD 680) and dry thoroughly.

weight engine oil.

b. Inspection and Repair.

(2) Reassemble the feed transmission in the

(1) Inspect all gears for cracks, chipped teeth

reverse of numerical sequence as illustrated in

or excessive wear.

(2) Inspect the bearings for rough spots or

b. Install the feed transmission as illustrated in

excessive wear.

( 3 ) Inspect the transmission cover and

(2) Refer to TM 5-3820-241-12 and install the

housing for cracks, breaks or other damage.

feed motor and feed chain.

(4) Inspect the idler gear shafts for excessive

(3) Refer to LO 5-3820-241-12 and service the

wear.

feed transmission.

(5) Inspect shaft keys and keyway in shafts

for excessive wear.

(6) Repair by replacement of defective parts.

5-6