TM 5-3820-241-34

and piston, and allows the piston to strike the

buffer ring with considerable impact, and often

breaking the the piston.

(b) Check the piston, cylinder, or buffer

ring for excessive wear by applying the cushion

test. This is accomplished by dropping the free

piston in the cylinder. The piston should bounce

or cushion on the air trapped between the piston

head and buffer ring. If the piston strikes the

buffer ring hard, the piston, cylinder lining or

buffer ring is defective and worn beyond safe

limits and they must be replaced.

(2) Piston Striking Face.

(a) Inspect the piston striking face to

make sure it is not chipped or cupped excessively.

A defective piston will damage every striking bar

with which it comes in contact. A stripped or

damaged striking bar will quickly spoil a good

piston.

(b) If the piston striking face damage has

not progressed so far, it can be repaired. If the

piston has never been reground, the striking face

must be squared up and flattened by careful

grinding. Perform the grinding operation slowly

to avoid overheating and annealing of the hard-

ME 3820-241-34/5-10

ened cast. Do not grind off more than 1/16-in. of

metal.

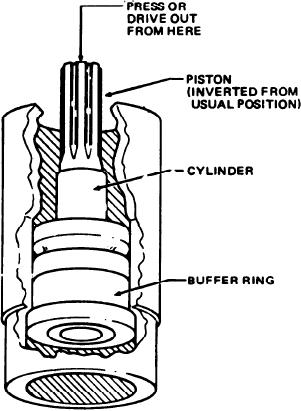

Figure 5-10. Removing buffer ring assembly.

(3) Rifle Nut and Chuck.

5-11. Drifter Drill Cleaning, Inspection and

(a) Inspect the raffle bar for a good fit in

Repair

the rifle nut, allowable wear depends to some

extent on drilling conditions. Lock the rifle nut

a. General. The drill engine should be

when you can slide a 1/8-in. shim between the

d i s a s s e m b l e d for cleaning and inspection at

flutes when these parts are engaged.

regular intervals, short of time when breakdown

(b) Inspect the splines in the chuck nut for

may occur. Because of varied operation con-

excessive wear. The piston bears on the splines in

ditions, inspection periods cannot be determined.

the chuck nut in the direction of rotation only, so

They can only be arrived at with accumulated

more nut wear can be tolerated. Replace the chuck

experience of the user, until safe cleaning and

nut if wear exceeds 1/2 the thickness of the

inspection intervals can be established. Drills in

splines.

d a i l y service must be returned to direct and

(4) Chuck Parts.

general support maintenance for disassembly,

(a) Inspect the chuck and chuck bushing

inspection and repair as required. In addition a

for excessive wear. When the chuck or bushing is

routine inspection for signs of excessive wear,

worn, alignment of the drill with the striking bar

scoring, broken or cracked parts must be made.

cannot be maintained. It will also cause chipping

b. Cleaning.

of the piston or striking bar and may shear off or

(1) Clean all p a r t s except O-rings with

cleaning solvent (Fed Spec PD 680) and dry

punch the air tube.

(b) Replace a c h u c k bushing if worn

thoroughly.

oversize or bell-mounted.

(2) Discard and replace all O-rings and seals.

(5) Motor Vanes.

c. Inspection and Repair.

(a) Inspect the motor vanes for excessive

(1) Buffer R i n g Cylinder and Piston.

wear. If the laminations show any sign of

(a) The most frequent reason for poor drill

separating, discard and replace with an complete

performance is that the piston, cylinder or buffer

new set.

ring lining have worn to such an extent that the

( b ) Inspect the sides of the vanes for

clearance between then has increased beyond the

indication of excessive milling. When a maximum

allowable wear l i m i t s . Excessive clearance

of 1/8-in. of the original vane width is worn away,

destroys the air cushion between the buffer ring