Section V. MAINTENANCE OF HYDRAULIC SYSTEM

3-10.

General

The rock drill hydraulic system consists of a hydraulic

pump, pump drive motor, pressure regulator, control

valve, reservoir, lift boom, swing, tilt, and extension

cylinders, and the necessary hoses and fittings. Refer to

figure 1-5 for a hydraulic system schematic diagram.

3-11.

Hydraulic Hoses

a.

Inspect the hydraulic hoses and fittings for

cracks, breaks or leaks. Presence of hydraulic fluid on

any of components or under the crawler indicates loose

fittings or damaged hoses.

b.

Check and tighten loose hydraulic fittings or

hose.

c.

Report

defective

hoses

to

organizational

maintenance.

3-12.

Hydraulic Pump and Drive Motor

a.

Inspect the hydraulic pump and drive motor for

secure mounting and leaks at the inlet and outlet fittings.

b.

Tighten all loose mounting hardware and fittings.

3-13.

Hydraulic Air Pressure Regulator

a.

Inspection. Inspect the pressure regulator for

secure mounting. Inspect the hydraulic and air hoses to

the regulator for secure mounting. Tighten all loose

mounting hardware of hoses.

b.

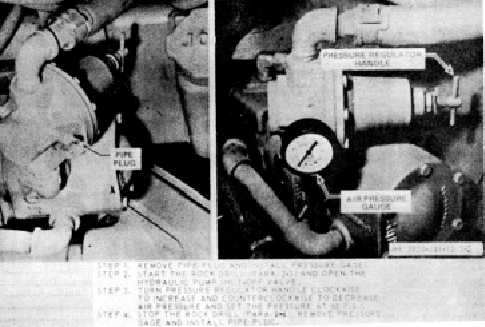

Adjustment. Adjust the air pressure regulator as

illustrated in figure 3-2.

Figure 3-2. Air pressure regulator adjustment

3-14.

Hydraulic Control Valve

Make a periodic inspection of the hydraulic control valve

to see that all hose connections and mounting hardware

are secure. Inspect hoses for ruptures or other damage.

3-15.

Hydraulic Cylinders

a.

The rock drill is equipped with {5 cylinders

consisting of lift, swing, tilt, extension and boom

cylinders.

b.

Check to make sure that all cylinders extend and

3-5