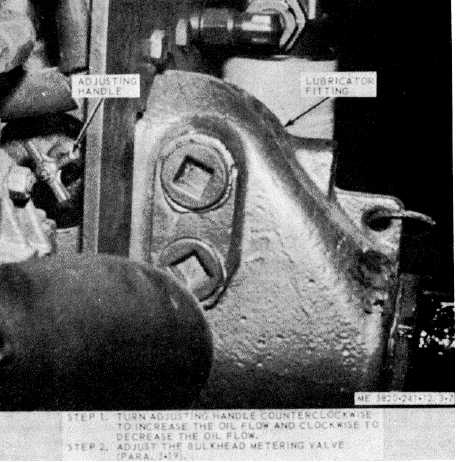

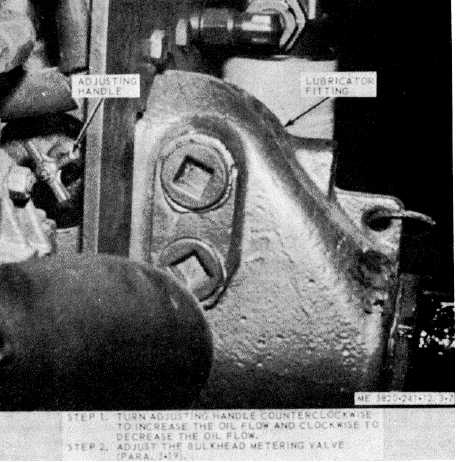

Figure 3-7. Air line lubricator fitting adjustment.

3-21.

Pneumatic Hoses

Inspect the pneumatic hoses and fittings for loose.

connections

or

ruptured

hoses.

Tighten

loose

connections. Report defective hoses to organizational

maintenance.

Section VII. MAINTENANCE OF LIFT, SWING, FEED AND LEVELING

MECHANISM

3-22.

General

a.

The lift and swing mechanism consists of a

pivot, boom assembly and dump assembly.

b.

The feed and leveling mechanism consists of the

feed assembly, centralizer, feed chain, drill trunnion and

sprockets.

3-23.

Lift and Swing Components

Inspect all pivot points, bushings and pins on the lift and

swing mechanism for damage or excessive wear. Report

all defects to organizational maintenance.

3-24.

Feed and Leveling Components

a.

Inspect

the

feed

assembly

for

damaged

components.

b.

Inspect the centralizer to make sure the arms

operate freely. Keep arm pivot areas free of dirt and

stones.

c.

Inspect the feed chain for proper adjustment.

The chain should have a slight sag at all times. If

adjustment

is

required,

report

the

condition

to

organizational maintenance.

d.

Inspect the drill trunnion for proper operation.

3-10