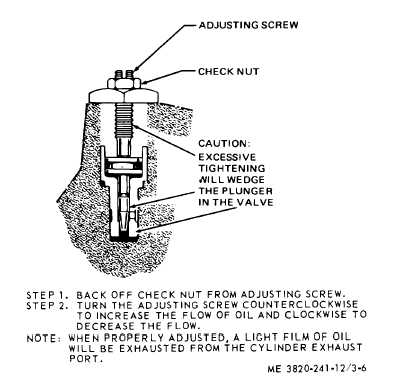

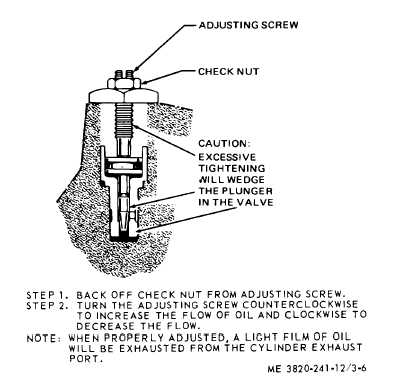

Figure 3-6. Bulkhead metering valve adjustment.

3-20.

Lubricator Fitting Adjustment

a.

Back off check nut on the metering valve (fig.3-

6) and turn the adjusting screw in until it bottoms in the

valve seat to shut off the oil supply.

CAUTION

Excessive

tightening

of the adjusting screw

will wedge the plunger

into

the

metering

valve and damage the

plunger.

b.

Activate the rock drill (para 2-5) until the drill

engine has warmed up sufficiently to produce an oil film

at drill engine exhaust port and on the shank of the

striking bar.

c.

With the drill engine thoroughly warmed up,

quickly retract the drill to force the hammer to operate on

cushion. If the lubricator fitting adjustment is correct, the

drill will diesel one or two cycles. This indicates that oil is

reaching the front end. If instead, the drill continues to

sputter for many cycles when retracted, the drill is

receiving too much oil and is dieseling heavily. Too

much oil may cause the drill to overheat and force of

combustion may even drive the piston against the valve

seat. If the drill is not receiving sufficient oil, no dieseling

will occur when the drill is retracted. There will be no

occasional sputter when hot and no random dieseling or

very little show of oil at exhaust and striking bar.

d.

Adjust the lubricator fitting as illustrated in figure

3-7.

3-9