TM 5-3820-241-34

the reverse of numerical sequence as illustrated in

nicks, and burrs. Remove small nicks with a fine

figure 3-15.

emery cloth.

b. Installation. Refer to TM 5-3820-241-12

(5) Inspect all hardware and threaded areas

and install the air motor.

for damage. Replace defective hardware retap

threaded areas or replace defective part.

4-4. Air Motor, Reassembly and Installation

a. Reassembly. Reassemble the air motor in

Section II. AIR PRESSURE REGULATOR

4-7. Air Pressure Regulator Cleaning, Inspection

4-5. General

and Repair

The air pressure regulator is an adjustable spring

a. Cleaning.

diaphragm type control that regulates the

(1) Clean all p a r t s except O-rings and

amount of air supplied to the hydraulic pump aid

diaphragm assembly in cleaning solvent (Fed

drive motor. It is mounted just above the air

Spec PD 680) and dry thoroughly.

motor and is normally set at 65 psi.

(2) Discard and replace all O-rings and the

4-6. Air Pressure Regulator, Removal and

diaphragm assembly.

Disassembly

b. Inspection and Repair.

a. Removal. Refer to TM 5-3820-241-12 and

(1) Inspect the valve and valve seat for

remove the air pressure regulator.

excessive wear or other damage.

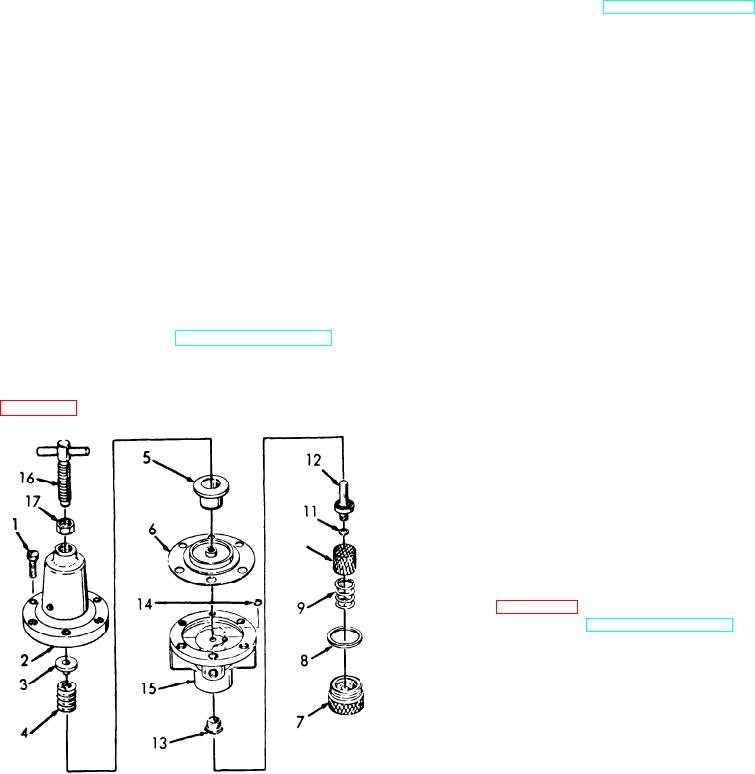

b. Disassembly. Disassemble the air pressure

(2) Inspect the strainer for holes or signs of

regulator in numerical sequence as illustrated in

excessive strain.

NOTE

Most pressure regulator failures can be

corrected by the installation of a new

d i a p h r a g m assembly, O-rings, valve

strainer and springs.

(3) Repair by replacement of defective parts.

4-8. Air Pressure Regulator, Reassembly and

Installation

a. Reassembly. Reassemble the air pressure

regulator in the reverse of numerical sequence as

illustrated in figure 4-2.

b. Installation. Refer to TM 5-3820-241-12 and

install the air pressure regulator.

ME 3820-241-34/4-2

9 Spring

1

Bonnet set screw

10 Air strainer

2

Bonnet

3

Spring rest

11 O-ring

12 Valve

4

Bonnet spring

5

Diaphragm rest

13 Valve seat

14 O-ring

6

Diaphragm assembly

15 Bonnet boot

7

Plug

16 Adjusting screw

8

O-ring

17 Locknut

Figure 4-2. Air pressure regulator. disassembly and reassembly.