TM 5-3820-241-34

(4) Replace all defective parts.

4-11. Tramming Motor Throttle Control Valve,

Cleaning, Inspection and Repair

4-12. Tramming M o t o r T h r o t t l e V a l v e ,

Reassembly and Installation

a. Cleaning. Clean all- parts with cleaning

solvent (Fed Spec PD 680) and dry thoroughly

a. Reassembly.

b. Inspection and Repair.

(1) Reassemble the tramming throttle valve

(1) Inspect the control handle plungers for

in the reverse of numerical sequence as illustrated

s c r a t c h e s or excessive wear, r e m o v e minor

in figure 4-5.

scratches with a fine emery cloth.

(2) Reassemble the tramming valve handle

(2) Inspect the plunger springs for breaks or

components in the reverse of numerical sequence

excessive wear.

as illustrated in figure 4-4.

(3) Inspect the valve body, valve and

b. Installation. Install the tramming motor

compression rings for nicks, cracks, or burrs.

throttle control valve in the reverse of numerical

P o l i s h minor nicks or scratches with a fine

sequence as illustrated in figure 4-3.

a b r a s i v e cloth. Replace compression rings if

cracked or chipped.

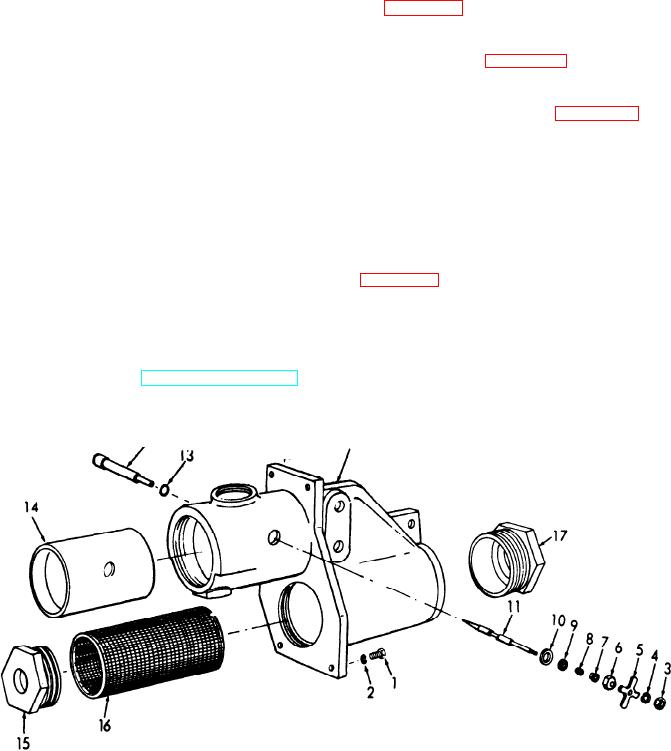

Section IV. LUBRICATOR FITTING

b. Disassembly. Disassemble the lubricator

4-13. General

fitting in numerical sequence as illustrated in

The lubricator

fitting, mounted at the rear center

of pneumatic

rock drill is an adjustable fitting

that filters the

air and controls the amount of air

and oil that is

introduced into the air system.

4-14. Lubricator Fitting Removal and Dis-

assembly

a. Removal. Refer to TM 5-3820-241-12 and

remove the lubricator fitting.

ME 3820-241-34/4-6

1 Hex head capscrew

7 Stem follower

13 O-ring

2 Lockwasher

8 Stem packing

14 Oiler bushing

9 Stem washer

3 Hex nut

15 Pipe hushing

4 Lockwasher

10 Stem seal

16 Oiler screen

5 Adjusting handle

11 Stem

17 Reducing bushing

6 Plain hex nut

18 Lubricator body

12 Valve body

Figure 4-6. Lubricator fitting, diassembly and reassembly.