TM 5-3820-241-34

equalizer bar and idler yokes for cracks breaks or

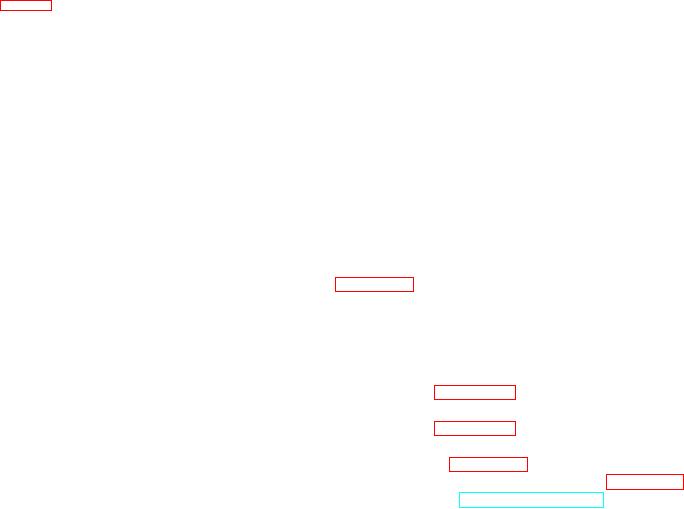

Legend for Fig. 6-6: (Cont'd)

35 Angle socket

17 Lubrication fitting

36 Spring pin

other damage.

18 Lubrication fitting

37 Pivot pin

(3) Inspect the idler springs and the idler for

38 Plain hex nut

19 Plain hex nut

cracks breaks or other damage.

20 Lockwasher

39 Lockwasher

(4) Inspect a l l h a r d w a r e f o r damaged

21 Hex head capscrew

40 Yoke mounting shaft

threads.

22 Plate

41 Lubrication fitting

23 Plain hex nut

42 Yoke

(5) Repair minor cracks on side frame

24 Lockwasher

43 Thrust washer

equalizer arm and equalizer bar by welding.

44 Idler oil seal

25 Machine bolt

(6) Replace defective hardware and other

45 Idler

26 Equalizer arm

parts.

46 Bronze idler bearing

27 Snap ring

28 Bronze bearing

47 Idler spacer shaft

6 - 1 2 . Crawler Side Frame and Equalizer,

48 Spring

29 Equalizer bar

Reassembly and Installation

30 Lubrication fitting

49 Spring cap

31 Snap ring

50 Cap O-ring

a. Reassembly.

32 Bearing

51 Backup leather ring

(1) Reassemble the crawler side frame in the

33 Snap ring

52 Shaft

reverse of numerical sequence as illustrated in

34 Oil seal

53 Shaft O-ring

(2) Use a suitable press to remove bronze

(2) Use a s u i t a b l e press to install bronze

bearings from track roller (14), equalizer arm (26),

bushings in the track rollers (14). equalizer arm

and track idler (45).

(26) and idler (45).

6-11. Crawler Side Frame Cleaning Inspection

b. Installation.

and Repair

(1) Install t h e equalizer arm and bar as

a. Cleaning.

illustrated in figure 6-5.

(2) Install th e crawler drive side frame as

(1) Clean all p a r t s with cleaning solvent,

illustrated in figure 6-4.

(FED SPEC PD 680) and dry thoroughly.

(3) Installl th e t ramming transmission and

(2) Discard and replace all oil seals and O-

rings.

brake housing (para 2-18).

b. Inspection and Repair.

(4) Install th e t ramming motor (para 2-14).

(5) Refer to LO 5-3820-241-12 and lubricate

(1) Inspect all bronze bushings for excessive

the rock drill.

wear and proper fit on shafts.

(2). Inspect the side frame, equalizer arm,

6-13