TM 5-3820-241-34

replace the complete set. Determine the extent of

wear by comparison with a new vane.

(6) Gears and Bearings.

(a) Inspect

t h e m o t o r s h a f t n e e d l e

bearings for excessive wear or other damage.

(b) Inspect all gears for chipped teeth,

excessive wear, or other damage.

(c) Inspect the bronze bushing in the

counter gear for excessive wear by rocking the

counter gear. Any excessive angular play will

cause rapid wear so the bushing must be replaced.

5-12. Drifter Drill, Reassembly and Installation

a. Reassembly.

(1) Coat all parts with a light film of oil

before reassembly. With the exception of press fit

bushings, all parts go together easily and will not

be forced.

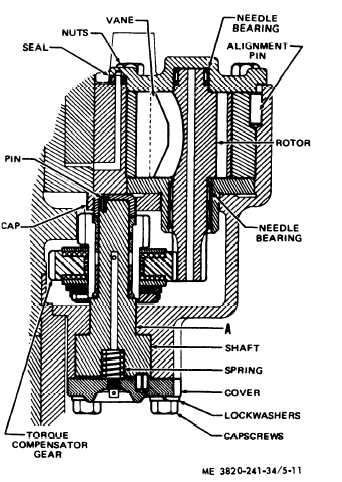

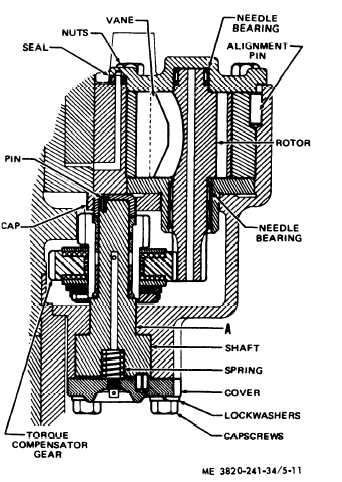

(2) Reassemble the drifter drill in the reverse

of numerical sequence as illustrated in figure 5-8.

(3) When assembling the torque com-

pensator counter (fig. 5-11) apply rock drill oil on

both sides of friction plates. Tighten locknut until

springs are flattened out completely. Then, back

off locknut approximately one flat until the set

screw hole matches the flat on the gear hub.

Install setscrew using Loctite Retaining Com-

pound. Lock screw tightly and place a drop of

Loctite on both back and front of setscrew. Bend

ears of lockwasher around locknut as shown in

figure 5-11.

(4) To assemble the dual rotation unit refer

to figure 5-11 and proceed as follows:

Figure 5-11. Reassembly of drill rotation unit.

5-16