TM 5-3820-241-34

(a) Insert shaft (fig. 5-11) through

opening, through the torque compensator gear

and into cap.

(b) Turn shaft until pin dowels into the

hole in the cap. Install spring, cover and secure

with four lockwashers and capscrews.

(c) Assemble needle bearings into motor

bearing support. Install motor bearing support

into housing, align support and housing and

install aligning pin.

(d) Install vanes in rotor, assemble needle

bearing on rotor, and install the rotor in the

housing. Make sure the seal in back cover is in

place and install back cover on the housing and

secure with four nuts.

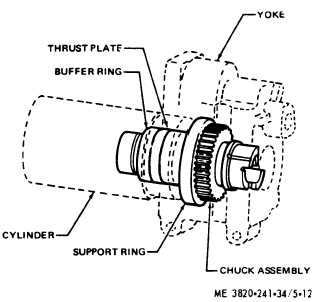

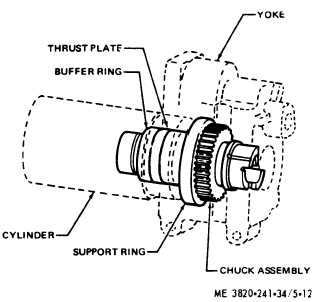

(5) To assemble the chuck parts refer to

figure 5-12 and proceed as follows:

(a) Assemble the support ring (fig. 5-12)

to the chuck. Install this assembly into the yoke

and tap into place until the support ring shoulders

in the housing. Install buffer ring in the cylinder.

(b) Position

t h e t h r u s t p l a t e i n

the

cylinder against the buffer ring. Position cylinder

in yoke (exhaust port towards the cradles) and

tap lightly until cylinder bottoms on yoke.

(6) Reassemble the piston, valve and

rotation parts as follows:

(a) Position the piston (41, fig. 5-8), in the

cylinder assembly (39), with flutes on piston

entered in slots on chuck nut.

(b) Hold locating pin (30) in the groove in

the cylinder assembly (39), line up slots in the

valve seat assembly (34) and valve block (33) with

locating pin (30) and assemble the valve into the

cylinder assembly (39). Tap into position until the

valve assembly seats on the cylinder lining.

(c) Install pawl spring (25). pawl plunger

(24) and pawls (23) into rifle bar (21).

(d) Install the rifle bar flutes into the rifle

nut (42) and install rotation release ring (20), into

ratchet ring (26). Line up ratchet ring with

locating pin (19) and tap into position against the

valve cover. Install support ring (27).

(7) Tighten

n u t s ( 9 ) a l t e r n a t e l y a n d

uniformly to 125 ft. lb. torque.

b. Installation.

(1) Install

th e drifter drill assembly in

reverse of numerical sequence as illustrated in

figure 5-7.

(2) Refer to LO 5-3820-241-12 and service

the rock drill.

Figure 5-12. Reassembly of chuck assembly.

Section IV. DRILL AND FEED CONTROL VALVE

5-13. General

The drill and feed control valve controls the drill

feed, blow, and rotation functions and is mounted

on the front end of the feed assembly.

5-14. Drill and Feed Control Valve, Removal and

Disassembly

b. Disassembly. Disassemble the drill and feed

control valve

in disassembly sequence as

illustrated in fig. 5-13.

a. Removal. Refer to TM 5-3820-241-12 ane

remove the drill and feed control valve.

5-17