(6)

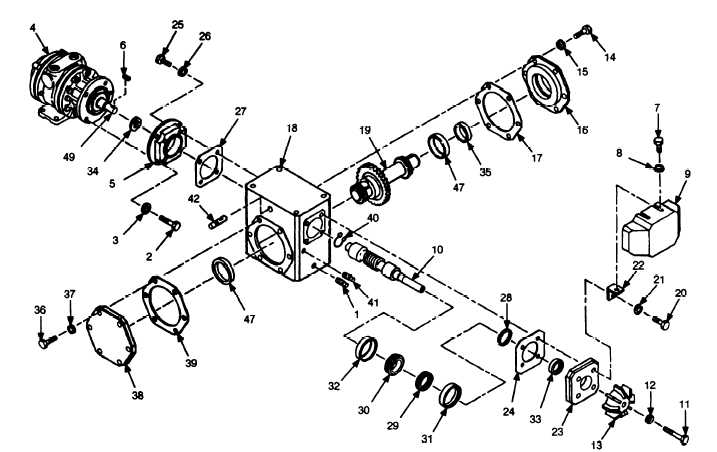

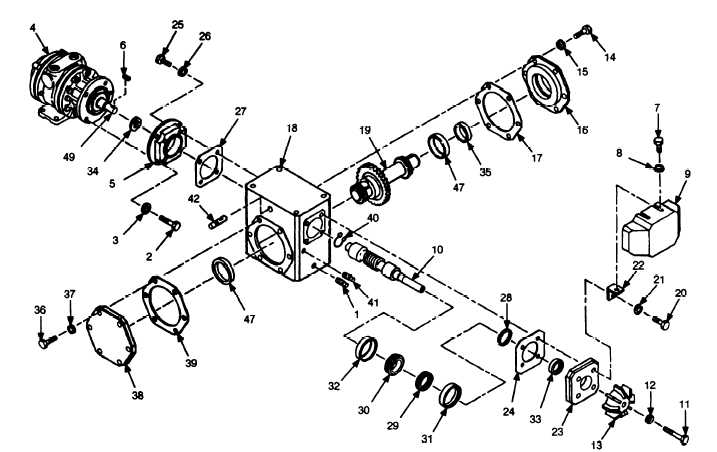

Install bearing cup (32), bearing (30), bearing

(29), and bearing cup (31) on quill shaft (10).

(7)

Install retaining ring (28).

(8)

Install new oil seal (33) in cover (23).

(9) Install cover (23), new gasket (24), and fan

brackets (22) on gear housing (18) using four screws (20)

and new lockwashers (21).

(10) Install new oil seal (34) in quill motor flange

5).

(11) Install quill motor flange (5) and new gasket

(27) on gear motor housing (18) using four screws (25) and

new lockwashers (26).

(12) Install shaft (19) in gear housing (18).

(13) Install new oil seal (35) in cover (16).

(14) Install cover (16) and new gasket (17) on gear

housing (18) using six screws (14) and new lockwashers

(15). Snug two of the screws and then check end play on

shaft (19). Adjust thickness of shim (17) until there is no

perceptible end play, then install and fully tighten screws

and lockwashers.

(15) Install fan (13) on quill shaft (10) using screw

(11) and new lockwasher (12).

(16) Install fan cover (9) on fan brackets (22) using

four screws (7) and flatwashers (8).

(17) Position gear housing (18) upright.

(18) Install key (6) in feed motor output shaft (49).

(19) Carefully position feed motor (4) for installa-

tion. Ensure that key (6) on feed motor output shaft (49)

properly engages keyway in quill shaft (10).

(20) Secure feed motor (4) to quill motor flange (5)

using four screws (2) and new lockwashers (3).

(21) Install feed motor and gearbox assembly (see

TM 5-3820-241-12).

(22) Service gearbox (see LO 5-3820-241-12).

14